Hi Everyone! This is Clint, your Sheet Metal Fabrication Technical Manager. We had an interesting sheet metal RFQ come in that I wanted to share with you.

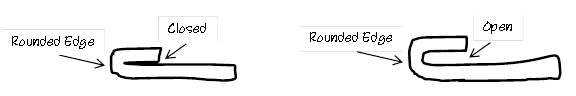

Have you ever had an application where you needed a sheet metal part with a curled edge? Sometimes customers want that rounded edge for extra thick edges, sometimes they want that thick edge to interlock with another part, and sometimes they want to use that opening in the rounded edge. In the sheet metal world, we call that rounded edge a “hem” and they come in 2 basic styles – a “closed hem” and an “open hem”.

Us sheet metal fabricators can make this kind of sheet metal feature pretty easily. We take a flat piece of metal and form it into an angle, then come down again on the angle to close it on top of the flat piece. If we want a closed hem, we come right down on top of the flat piece. If we want an open hem, then we come down on top of a spacer (an extra piece of metal the thickness you want the opening), then we slide out the spacer.

The tricky bit for any sheet metal fabricator is when you want the sheet metal we’re forming to be thick. Generally any sheet metal over 1/8” thick could have micro-cracking on the outside of the rounded edge (aka the outside of the hem). Steel parts generally have less issues with micro-cracking than aluminum.

For you sheet metal engineers, these micro-cracks occur because the inside of the hem is under compression and the outside is under tension. Once the bending force exceeds the yield strength of the material (necessary to bend any sheet metal), you’ll get these micro-cracks. The part works fine, but if you look close enough, you’ll notice them. Plate the part and you’ll notice it more.

All sheet metal comes with a grain from the processing mill, so we can reduce any micro-cracks if we form the hem opposite of the grain. Yes, you could probably reduce the micro-cracks if you heated the tool or the sheet metal (yes, we have been asked that!), but please don’t ask. Controlling heat for consistency is difficult and could be dangerous. A better way for a sheet metal fabricator to reduce micro-cracking is to make the hem incrementally, by using multiple hits on the press brake tool (a.k.a. “bumping”) to gradually form the radius.

Going into production with a design feature like this? There is help! This feature is common enough that the punch press tooling companies have special tooling that can form these hems in the punch press. So much faster and so much more consistent than doing this in the brake! There are some exceptions – this really only works for thicknesses 0.062” or less and your part geometry needs to allow space for this tooling to work. As always, give me a call and we can help you through it. My number is 978-486-9050.

from ETM Manufacturing http://etmmfg.com/3755

No comments:

Post a Comment